Roller solutions tailor-made

Manufacture and distribution

of components for conveyor and bearing technology

FMG Förderelemente Mecklenburg GmbH was founded in 1991 and is a company specialised in the manufacture and distribution of components for conveyor and product storage technology. Whether for machinery and system constructors or system operator of all industry sectors in all parts of Europe:

Due to the high degree of vertical integration of the inhouse production, tailor-made solutions for all needs are delivered with convincing flexibility and a consistently high product quality.

Rollers for

conveyor and storage technology

FMG develops and manufactures individual conveyor technology and storage technology elements, which are characterised by the high quality and long service life of the support rollers. Unique and pioneering products are created under consideration of the specific customer requirements.

The product portfolio includes both standard rollers, which are manufactured in accordance with the corresponding DIN standard as well as special orders for customer-specific requirements and area of application.

Roller solutions in many variants

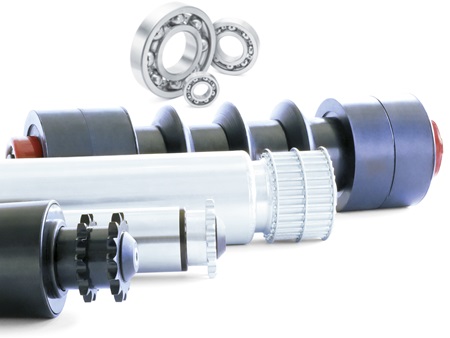

FMG support rollers are essentially comprised of three components: the bearing, the pipe and the axle. LFD bearings are designed optimally for the requirements of the conveyor technology and logistics sector. Detailed specifications on these individual components are required for the construction of a support roller with the respective length dimensions in accordance with the customer’s specifications.

Due to the specified order nomenclature in the detailed FMG catalogue and the online configuration software, which can be loaded and used on the manufacturer’s homepage, it is possible to describe an accurately delimited support roller.

This is supplemented with the precise designation of the type range of the matching LFD bearings. This applies to both driven as well as non-driven rollers. On its own homepage www.LFD.eu, LFD offers a complete database.

Production according to DIN-standards

Noteworthy during the construction

The company supports customers with advice as many points must already be observed during the construction.

In the framework of the construction, the following is advisable...

- Pay attention to axle parallelism.

- Pay attention to the same roller level.

- In regard to profiles, pay attention to the parallelism of the roller conveyor profiles.

- Do not use accumulation rollers alternating with non-driven support rollers.

- Take environmental influences (dust, moisture, temperature, acids, bases, etc.) into account.

- In regard to the running properties, pay attention to different roller resistance of the bearings (sealing,

lubrication). - Pay attention to pipe tolerances, take the standards into account (DIN EN 10220, DIN EN ISO 1127).

- Pay attention to the maximum roller length with plastic pipes (pipe loads) and temperatures.

- Pay attention to the maximum pipe length with steel pipes (pipe loads).

- Take the discharge variants into account in the event of electrostatic charging.

- During the roller distribution, pay attention to the axle distances according to the conveyed material.

- To ensure smooth transportation, plan at least 3 rollers below the conveyed material at all times.

- The measuring chain must be taken into account in the event of driven support rollers with accumulation or fixed drive in the press fit between the installation length (EL) and the roller length (RL) using the table value, to prevent the drifting apart of the support rollers.

The following must be taken

into account in the framework of the construction:

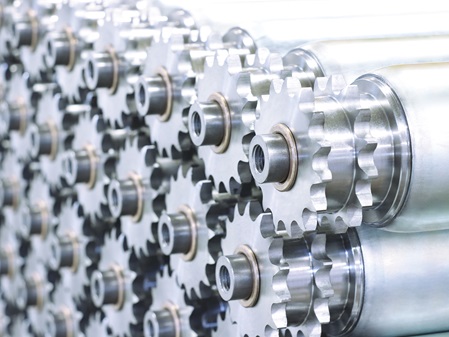

- Tooth type – rack-and-pinion gearing only with tangential drive

- Welded support rollers – weld seams can be larger than the pipe diameter

- Connections – press fit of sprockets only with continuous transport

- High temperatures – plastic components of the support rollers

are not suitable for higher temperatures - Adjustable accumulation rollers – in the event of uneven running surfaces and light weights

- Drive – note and observe the tolerances in the event of chain drive and toothed belt

- Pay attention to the failing load of chains

- Level running surfaces – not all rollers will support the load in the event of uneven running surfaces

- Position the motor as centred as possible

Reliable

radial load capacity

Generally, LFD deep groove ball bearings are the safe choice. When more inexpensive LFD deep groove ball bearings are used in lieu of LFD spherical roller bearings in borderline cases with particularly heavy goods, it should always be examined precisely whether the installed ball bearings are suitable in regard to design, performance and load in the respective application.

As is known, different bearings also fit in the different housings. When rollers have a deflection capacity, then the reliable radial load capacity of the deep groove ball bearings or spherical roller bearings is a deciding factor.

LFD ensures these requirements with its own laboratory equipment and test benches. Nevertheless, spherical roller bearings are more flexible than deep groove ball bearings. Therefore, in the event of especially heavy loads, a consensus must be reached on what the respective bearing must be able to absorb and by which factor the axle may deflect.

Here, spherical roller bearings are able to absorb significantly larger deflections without damage being inflicted on the conveyor line.

For average loads, usually the LFD Standard deep groove ball bearings are the right choice, both for cost reasons as well as for the goods to be conveyed and the durability of the conveyor elements.

LFD bearings with labyrinth seals and V groove

LFD bearings: application-optimised

LFD has implemented the labyrinth with the special inner race form in the so-called V groove. A friction seal can engage in the V-shaped recess or the contour of the sealing lip follows with the gap to the V groove. This non-friction variant, which is still very efficient is called the RZ seal. This is for example used in rollers of gravity conveyors in parcel distribution centres worldwide, on which even with only a slight incline, goods can be conveyed without the application of great force. RZ seals are useful in all applications in which performance losses due to seals are undesired and the expected degree of contamination is not significant.

Long service life under continuous load

Comprehensive support roller Portfolio

for various industry sectors

Bulk material

- Idler rollers

- Belt guide rollers

- Buffer ring rollers

- Support ring rollers

- Belt stations

- Driving drums

- Deflection drums

Parcel goods

- Non-driven support rollers

- Driven support rollers

- Conical support rollers

- Buffer ring rollers

- Support ring rollers

- Small conveyor rollers

- Multi-directional rollers

- Roller tracks

Additional components for conveyor and storage technology

A suitable powerful sealing system for the reliable and efficient use of the FMG rollers is offered for all areas of application. The product range is supplemented by plastic rings, support rings and buffer rings, which FMG equips the support rollers with according to the customer’s wishes before delivery. A large selection of different ring sizes and properties fulfils the entire range of the customer requirements.

Extensive machinery

Additional CNC lathes, automatic welding machines with corresponding extraction and welding power sources, automatic thread-cutting machines and steel washing machines enable an extensive vertical integration of manufacture during the production of the conveyor elements.

Online configurator

When no further details are provided in the catalogue or the online configurator of the company on the bearings or drives, then as standard, 2Z sealed deep groove ball bearings are installed.

When bearings or drives are to be produced in specific ball bearing qualities or the steel bearing holders or drives should be made of a material type other than steel, then this must be performed following the respective type range.

Ball bearing qualities: drive or counter-bearing variants

Other ball bearing qualities can be:

- 1Z – sealed

- Standard: 2 Z – sealed (standard)

- RS: 2RS – sealed

- D: Ball bearings made of plastic with NIRO balls

- NZZ: 2Z – sealed ball bearing made of NIRO

- NRS: 2 RS – sealed ball bearing made of NIRO

- PR: Spherical roller bearings – cylindrical 2RS sealed

- PKK: Self-aligning ball bearing – conical with clamping

sleeves - PK: Self-aligning ball bearings – cylindrical 2RS sealed

- PRK: Spherical roller bearing – conical with clamping

sleeves

- Made of steel, uncoated

- I: Made of steel, electro-galvanized

- N: Made of NIRO (V2A)

- N4: Made of NIRO (V4A)

- KS: Made of plastic

Coating services

As standard, FMG support rollers are produced in various RAL colours, which are applied on-site using a two-component paint system. Of course additional coatings can be implemented in-house and in cooperation with specialist partner companies – e.g. electro-galvanizing or rubber coatings.

A process innovation was achieved in the framework of a device for the fitting of PVC hoses on steel conveyor rollers.