Plastic wheels in a wide variety

Colourful product development

with innovative competence and great expertise

The need for different plastic wheels both by industry as well as by consumers is nearly unmanageable. Here, not only load capacity and running characteristics play an important role, but also the design.

The toy industry alone demands a variety of colourful wheels, which not only offer functionality, but also act as design objects in the overall product.

Many wheels are closely attuned to the colours of the corporate design of a specific company, others, for example in the care sector, must be especially quiet, low-maintenance, clean and discreet.

Plastiv wheels for industrial applications

Strict requirements for wheels

Device wheels

The device wheels made by MP-Plast have been developed to support devices and equipment with a load from 40 kg to 350 kg. They are suited for the movement on flat surfaces, where silent and easy movement is an essential requirement. The wheel was designed with a classically beautiful styling and in itself is a design element, without focussing on the product, which it carries. All device wheels are manufactured in different sizes and in a large selection of material compositions, which all have their own good properties.

Reliable and robust wheel series

More than 30 years of experience in the production, development and construction of plastic wheels in a multitude of variants and other plastic products are featured by the family business MPPlastin Ribe in Denmark.

Due to comprehensive innovative competence, in the course of the years, the managing director Max Petermann developed different wheel programmes, which were developed with his extensive expertise and market knowledge. Therefore, for generations, the name Petermann has been synonymous with high quality and product development in the plastics industry. With remarkable own creativity and many own patented developments, the company provides reliable and ro bust wheel series, which are characterised by an attractive design, a large selection of colours, good quality and optimal functionality.

In many cases, a wide standard product range makes it possible to find precisely the right wheel for the respective application, which will meet all requirements.

Development up to readiness for production

When a customer-specific product is required, the company has proven that it is capable of developing a completely new project up to the readiness for production. From the drawing of the product, through the material selection up to the manufacture of the necessary tooling and the production in large quantities.

In Ribe in Denmark, production is performed using the latest and most modern injection moulding machines, which enable a clamping pressure of 40 to 400 tonnes and a shot weight of 2.5 kg. Rims, PP wheels, PA wheels as well as heat-resistant wheels and many more items are produced in 1-component injection moulding machines. A wide array of machinery with 2-component injection moulding machines, on which the clamping pressure is 400 tonnes as well as the shot weight of 3.0 kg per cylinder, fabricates the manufacture of products with large surfaces and weights.

LFD bearings

Low noise, easy running and heavy duty

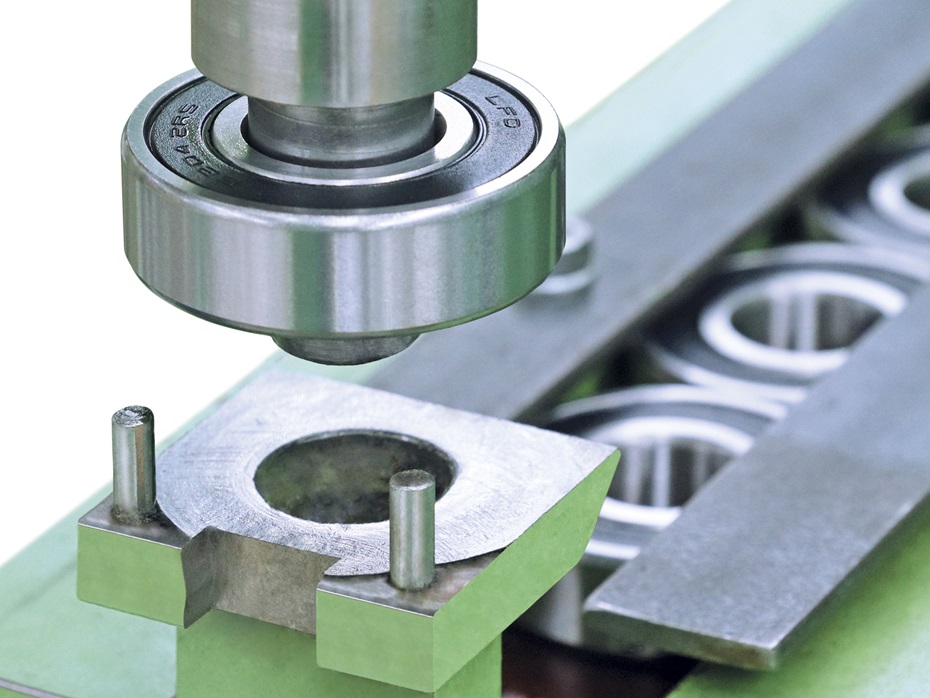

It poses a technically difficult challenge when a ball bearing is to be moulded in; experts agree on this. This is also not possible with all ball bearings, as in principle oil and water are brought together during the injection process. Here, work is performed with injection pressures of several 100 bar and very high temperatures of approx. 200 °C. These operating steps present extreme loads for seals and the grease in the bearing.

Many plastics are hygroscopic and absorb water. Only with the water content in the plastic does this achieve its properties such as impact strength, elasticity and abrasion behaviour. To be able to perform the conditioning of the plastic (with warm baths) with injected layers, attention must be paid to the use of bearings made of stainless and rust inhibiting steels respectively.

Strong functionality

in all environmental and working conditions

Easy transport due to reduced rolling resistance

However, a conditioning of the injected bearing is also possible in an unspectacular manner, by simply putting the bearing that has been encased into interim storage for a certain period. In the course of this, the hygroscopic plastic will absorb the moisture on its own and in this manner will also obtain its necessary properties.

The only sensible alternative is to inject the plastic rings on their own, to press in the ball bearing separately and subsequently to secure it mechanically. In this manner, the manufacturer in the roller and wheel industry also has a greater choice in the selection of the bearing, the greases and the plastics.

A precondition of course is that all other requirements in regard to the bearing are met. Incidentally, in safety-relevant areas, LFD bearings are encased in fire-protected plastics, as other normal plastics are highly combustible. A decisive factor in regard to the use of the ball bearings in wheels are therefore not only the construction, but especially the quality of all involved components.

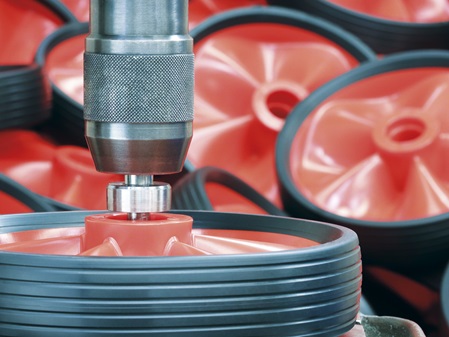

Rubber rollers

The rubber wheel is the latest member of the MP-Plast wheel series and due to its simple and modern design has been well-accepted by industrial customers, which has led to a very positive demand situation.

The wheel is a truly good alternative to a solid rubber wheel and stands out with a considerable price advantage. The rubber wheels are smooth, low noise and provide exceptional operating comfort. Simultaneously, it complies with all REACH requirements.

Rims

In the course of the years, a robust and dynamic range of plastic rims was developed. MP-Plast offers plastic rims in a variety of sizes, as a result that they fit on 4, 6 or 8 inch pneumatic tyres.

It is due to the dynamics of this plastic rim, in particular the 71 x 35 model, which make it especially competitive. Here, different covers have been developed in such a manner that the customer can achieve the desired hub length, which makes the rim very versatile in its function. A hub length of 73 mm up to 100 mm is possible. Furthermore, the Ø dimension can also be modified.

LFD: PX-Design

ensures the guide accuracy

LFD ball bearings encapsulated in plastic

An additional area of application for LFD deep groove ball bearings encapsulated in plastic lies with manufacturers of nursing and hospital bed rollers or doctor’s surgery equipment as well as of medical equipment.

Here, LFD has improved its PX design for even more guidance stability with rollers and wheels.

Due to the optimal construction selection of the ring geometries and the available rolling elements, it is achieved that the deep groove ball bearings produced in accordance with the PX design, only allow extremely small tilt angles. As a result, the wheel is guided in a stable manner and is no longer affected substantially by the installation conditions as it would be with standard bearings.

The PX design ensures the guide accuracy with low-friction wheels. Due to the optimal construction selection of the ring geometries and the available rolling elements, it is achieved that the deep groove ball bearings produced in accordance with the PX design, only allow extremely small tilt angles and as a result a wheel runs with guide stability.

Widely dispersed areas of application

The requirements are especially strict with manufacturers of nursing and hospital bed rollers as well as on medical equipment: Because in addition to high corrosion protection requirements, specific requirements are also set in regard to the smooth running behaviour. These wheels usually are made of deep groove ball bearings encapsulated in plastic.

The areas of application of these specific precision wheels and rollers with PX design bearings are widely dispersed: In addition to hospital beds, they are utilised in shopping trolleys, wheelchairs, prams, warehouse carts, office furniture, office chairs, furniture in general, in luggage transport and many other applications.