POWER. PRECISION. FLEXIBILITY.

Continuous innovation of products and solutions as a decisive factor of intra logistics

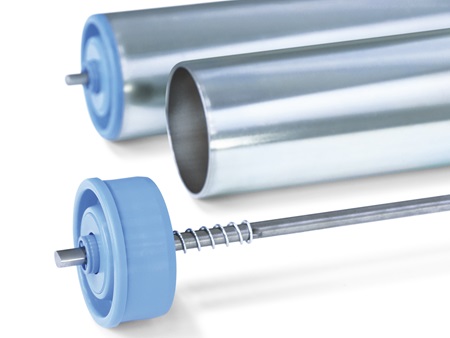

Each modern company must design its in-house transport processes, which are in regard to the movement of material and goods, in a manner that is as efficient and time-saving as possible. From the viewpoint of competitive reasons alone this is indispensable. An aid in the problem solving by means of intra logistics is the use of belt conveyors with support rollers. They enable both a linear as well as a curved operation. Conical support rollers are used for the implementation of a curve-shaped movement, with the use of which the radii of the curve movement can be varied within certain limits.

Ideal Transportsolutions for each industry sector

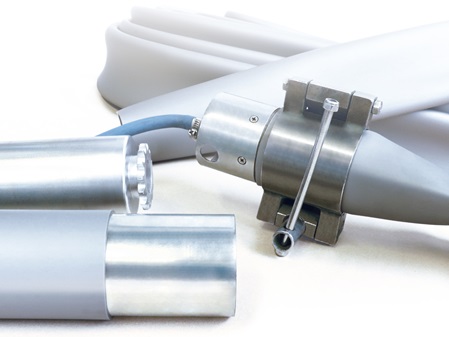

TRAPOROL is a specialist and leading manufacturer of support rollers, motor rollers, expansion elements and accessories for conveyor technology systems. The products with a wide portfolio are utilised in many industry sectors, e.g. in the food industry, automotive industry, chemical and pharmaceuticals industry, in wood processing and furniture industry, packaging industry, printing and paper industry and in the stone in- dustry.

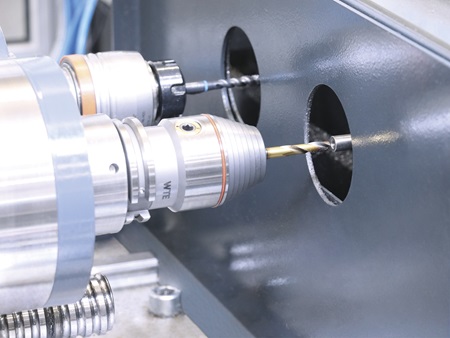

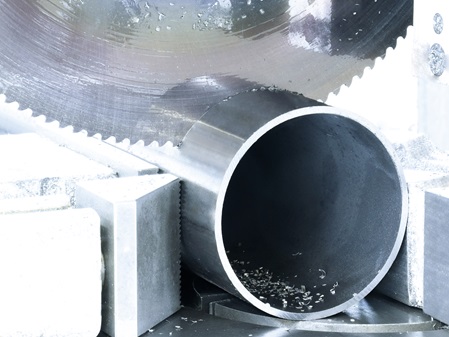

With extensive in-house vertical integration, the standard product range of support rollers and elements of conveyor technology already covers a multitude of customer requirements. As a developer of individual solutions with specific requirements, the company can quickly provide tailor-made products. Long-term experience enables ideal transport solutions for all needs.

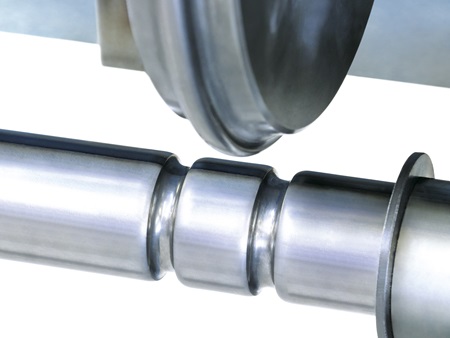

Support rollers with ribbing

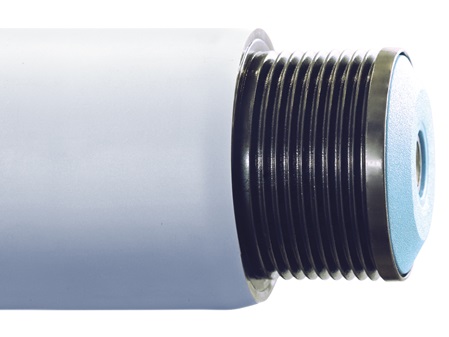

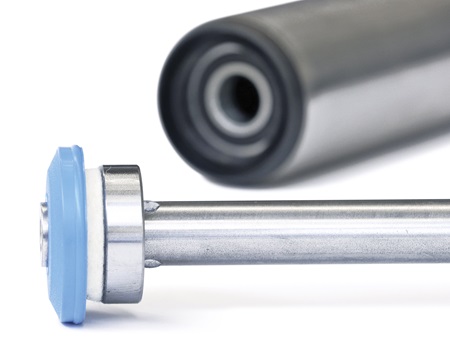

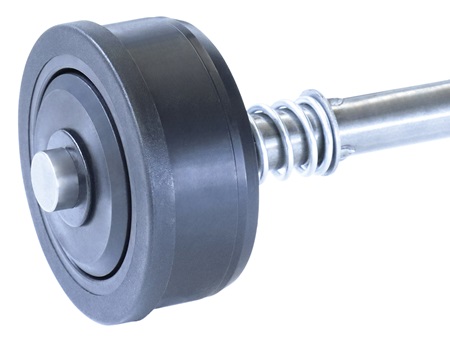

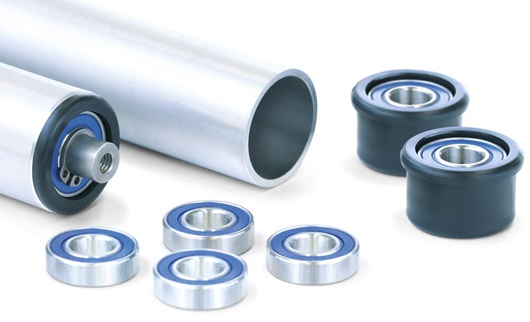

Support rollers with single or double ribbing from in-house production in combination with a round-section belt result in a roller conveyor for light and moderately heavy conveyed goods. The operation is not only especially safe, efficient and fast, but also almost completely silent. The bearing insert is comprised of a plastic roller base (polypropylene) with plastic seal (polypropylene) and deep groove ball bearings DIN 625, optionally with deburred roller bases. [Deburred roller base = Recommendation for lateral sliding on]

Exclusive special solutions

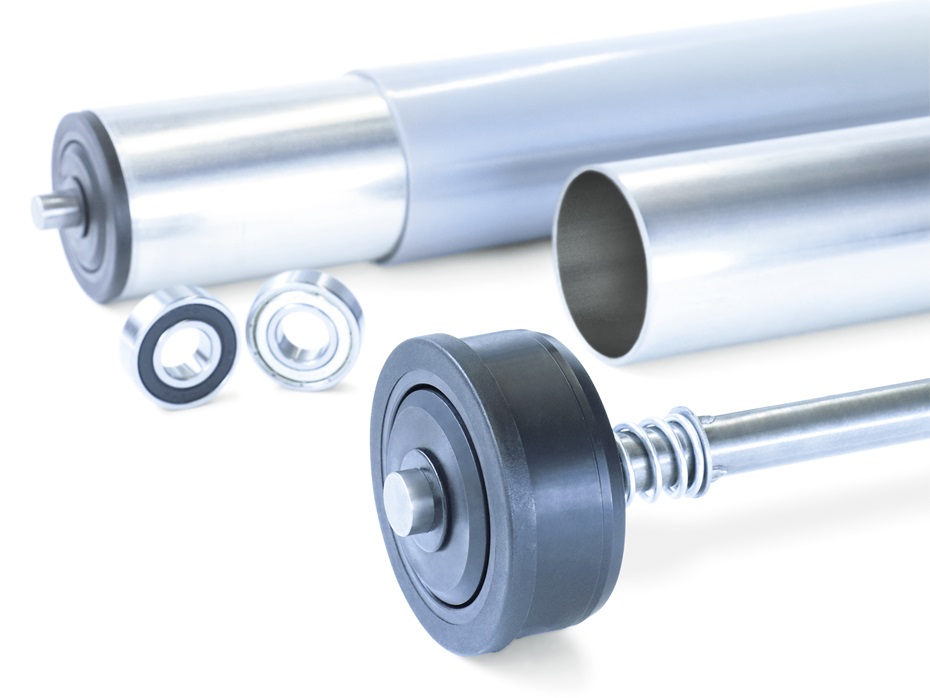

Support rollers for conveyor and goods flow systems

Support rollers from TRAPOROL are a perfect choice for the implementation of conveyor and goods flow systems. In addition to a flawless finish this is also due to a high degree of individualisation of the products in regard to the respective applications. They are adapted precisely to the requirements of the conveyed material and the customer in regard to size, material and surface quality.

Development of exclusive special solutions

Even for especially harsh operational environ- ments such as salt mines, it was possible to devel- op conveyor solutions, which in regard to through- put, robustness and durability are unique.

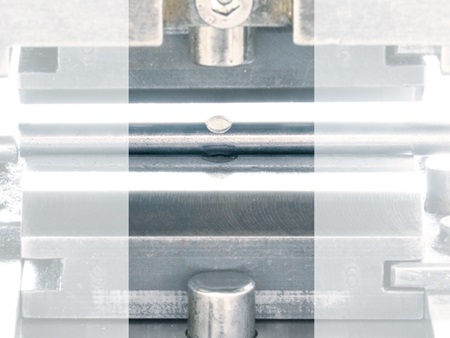

Even in such conditions, LFD ball bearings can ensure reliable operational performance. LFD had the function/corrosion behaviour tested in a 4-week climatic test. During this test, the ball bearings of both the market leader as well as a rolling bearing manufacture and additionally of LFD were tested. Here, the best results were achieved by the LFD bearings with seal and greasing using Klüber Staburags NBU12K

The loading capacity of a support roller is of course determined by the respective load values of the utilised components, bearings, pipe and axle.

As a result of the in-house production, short de- livery times of original spare parts are possible, of which in the event of the need, contingents can be kept in the warehouse, but additionally due to individual manufacture workplaces can be pro- duced promptly and exactly. But also spare parts for third party systems are produced according to samples or technical drawings

The specifications for the correct LFD bearings are each list- ed with the corresponding series in the catalogues. No limits have been set in regard to the technical and creative knowledge. During the entire development process, competent employees are in close con- tact with the customer to meet all necessary requirements as desired and in particular in achieve an economical implementation.

With full effort particular stability

Individual coatings and surfaces

The true efficiency of a conveyor system lies in the perfect balance of the conveyor elements to the conveyed material. Special roller coatings are required for the safe and quick transportation of especially sensitive components such as high gloss kitchen fronts, but also paper-coated furniture. TRAPOROL offers a variety of special coatings for such specific applications, with which the transport rollers are equipped.

Perfect Equipment down to the detail

No scratches, abrasions, traces of oil or other damage may be inflicted on the specified goods. Whether made of plastic, fabric or with a surface treatment – the entire range of possibilities for a perfect transportation and the comprehensive protection of the conveyed material is offered. Generally, the support rollers are suitable for heavy conveyed material and high rotational speeds. The bearing insert for example is comprised of a plastic roller base (polycarbonate) with a plastic seal (polypropylene) and an LFD deep groove ball bearing. The bearing insert is also available with a galvanised sheet steel roller base with plastic bearing bushing (polypropylene) and with LFD deep groove ball bearings in accordance with DIN 625.

Drive and conveyor chains made to measure

At TRAPOROL, the customer optionally receives precisely the correct conveyor and drive chains matching the respective transport rollers. Here, each chain has been tailor-made in regard to the material and variant exactly for the required operation purpose. In this manner, the maintenance costs are lowered significantly and the capacity of the respective transport systems is maintained. Whether by the me- tre or cut to length and enclosed, ready-to-fit: All available chains are produced ac- cording to DIN ISO 606 (formerly DIN ISO 8187) and meet the strictest requirements.

Individual conveyor solutions

TRAPOROL GmbH is not only a manufacturer, but also a leading developer of high-quality products and innovative solutions for the sector of conveyor technology accessories. Decades of experience and comprehensive knowledge of the most diverse industry sectors and industries lead to universal problem solutions for all issues of modern goods transfer.

Automation with high-quality LFD ball bearings

The production is adapted specifically to the respective customer. Individual modules and expansion modules for complete conveyor technology systems are adapted precisely in regard to size, material or surface structure of the respective requirements. Here, modern production facilities “Made in Germany” ensure the quick and competent development of even very specific solutions.

Depending on the lifting capacity of the rollers, different requirements apply to the utilised LFD bearings. Average support rollers with an axle diameter of 8 mm to 17 mm are often equipped with LFD deep groove ball bearings, which are fitted with a labyrinth or double labyrinth seal (Z / ZZ / RS / 2RS). The suitable application-specific design of the ball bearings is determined with the consultation of the engineers of LFD- Wälzlager GmbH. The pipe material itself can also be selected in a wide variety of variants and coatings.

Efficient processes continuous quality

A competent team of engineers, developers and technicians at TRAPOROL continuously improves the quality of the in-house standard components and additionally delivers product innovations that provide clear advantages - in regard to handling, the efficiency of the processes and the reduction of running costs.

Quality management according to German standards is also a matter of course for all production sectors of the LFD Group. For the verification, optimization and for new developments, the LFD Group continuously expands its own development laboratory with the latest measurement technology made by renowned manufacturers and different test benches, which are constructed in close cooperation with notable universities.

Quality, cooperation and certification

Many years of experience as well as the tireless commitment of the employees are reflected in the quality of the products. The collaboration with universities and research institutes, the permanent further training of the employees, the use of modern IT tools (e.g. CAD systems, simulation programs) and last, but not least, the continuous improvement process of the products and processes serve a single goal: Satisfied customers and the smooth operation of the conveyor elements and components.

The certification by the TÜV reflect this quest for quality. TRAPOROL has been certified according to DIN EN ISO 9001 since 2001. Most recently, in June 2018, the company received its new certification for DIN EN ISO 9001:2015.