SUPPORT ROLLER BEARINGS

FROM SPECIALISTS

In reverse drawing, die stamping and plastics engineering, MARKES produces both simple as well as complex solutions for conveyor technology

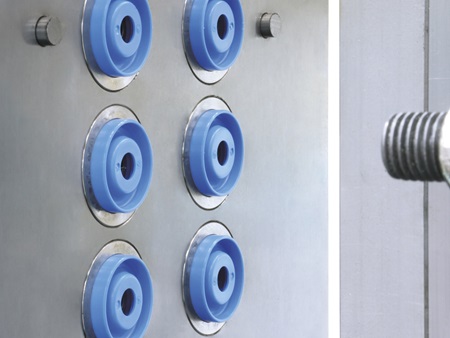

Support roller bearing in different variants

The solid roller bases from in-house production are popular. The MARKES company supplies wide ranges of the roller industry, consults with many decades of experience in regard to suitable material selection, geometry, dimension and tolerance design and offers feasibility studies on the production up to the development of process and cost-optimised products.

Whether support roller bearings, bearing holders, small running rollers or special ball bearings, the product diversity is large. With MARKES, you can be sure that you will receive the article that meets your expectations.

MODERN PRODUCTION ENVIRONMENT

Precise forming technology

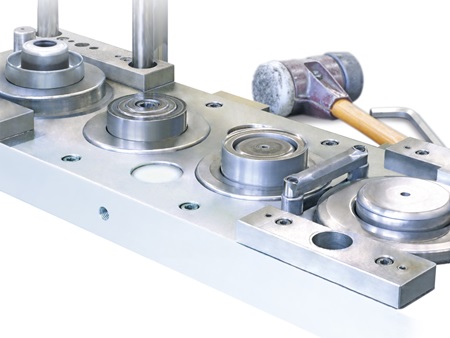

Extensive, exemplary machinery produces especially solid and stable bearing holders with own tool forms for among others the bulk goods industry, which for example are simultaneously are holders for reliably durable LFD bearings.

The raw material is inserted automatically directly into the thermoforming machine from large metal reels and then shaped in several steps into the final roller base.

MARKES is one of the few manufacturers that are able to produce these large quantities of bearing holders with an enormous speed and simultaneously of such high quality. Roller manufacturers worldwide are supplied with these stable solutions in large batches.

Precise plastics engineering

Similarly, the company is specialized in the area of plastic. For more than 50 years, complex injection moulded parts including the corresponding tools are developed and pro- duced according to the customer’s specifications.

A highly modern production environment safeguards consistent quality and technical production quality with all plastic parts.

PRECISION FOR ALL REQUIREMENTS

Quality

MARKES produces products at the highest technical level. Integrated production processes from the development through the tool making up to prototyping, series or individual manufacture are controlled and monitored by the in-house MES (manufacturing execution system). Together with a high degree of automation, the foundations are laid to ensure that the customer remains competitive with the products.

Here, MARKES does not only manufacture the individual components, but rather these assemblies are also assembled on-site.

Intra logistics

Hardly any industry sector has such potential for saving and streamlining as intra logistics. Both to the public as well as to many users, the potentials of the internal flow of material and the logistics are often insufficiently known. Intra logistics is the future-oriented term in conveyor technology.

Because this industry sector in Germany alone in cludes thousands of companies – from the manufacturers of lifting equipment and cranes to the producers of forklift trucks and storage technology as well as software developers up to complete system providers.

In gravity conveyor systems and motor-powered conveyor systems of the storage technology ranging from floor conveyor systems, continuous conveyors, order picking and packaging systems to palletising systems, the modern intra logistics solutions provide reliable services.

SUPPORT ROLLERS

AND BEARINGS TEST BENCHES

Test benches for rollers

Precaution for the practice in the application: With the test benches made specifically for MARKES, different load cases of the conveyor roller can be simulated according to the specific needs of the customer. In this manner, it is ensured from the outset that the utilised bearings meet the high demands of the customers.

Bearings with excellent technical values

Especially a seemingly insignificant production part such as a ball bearing often determines the efficiency of an entire conveyor system.

With its in-house laboratory equipment and test benches, LFD is able to meet with the highest quality require- ments. The structure-borne noise diagnostics is a recognised analysis procedure and is used for the condition monitoring of rotating bearings. With light axial preload, a fixed outer race and a rotational speed of 1,800 rpm, the LFD deep groove ball bearings are measured using in-house test benches at determined frequency bands between 50 Hz - 10,000 Hz.

In the analysis, the frequencies summarised in the low band as “long waves” provide insight into the geometrical trueness and in the high band as “short waves” provide insight into the surface roughness. The noise emission with LFD EMQ deep groove ball bearings has been extremely reduced in regard to the application in gearboxes and electric motors. Elementary for this is an excellent surface finish and the high geometrical trueness.

Bulk material systems

The use under the harshest conditions must be safeguarded for the preservation of the process chain in bulk goods systems. In the course of this, quality and economic feasibility are always at the centre of attention.

The company offers a high degree of availability of its spare parts. In addition to the robust bearing holders, MARKES also offers bearing seals for the use in conveyor belt rollers, which can be utilised in support roller stations, bottom belt roller holders, guide stations and belt guide systems. All of this is featured in the extensive portfolio.

A practical example: A conveyor belt with an overall length of 3.4 km and a width of 800 mm conveys a load of approx. 750 tonnes/h with a velocity of 2.9 m/s. Safety and reliability are the most important parameters in such a process.

DEEP-DRAWING TECHNOLOGY AND STAMPED PARTS

Experience as a basis for product solutions

Economic quality and precision in deep drawing, reverse drawing and die stamping technology is the result of decades of experience and the reliable industrial production lines.

MARKES provides support to the support roller industry from the idea through the development, the prototyping and tool construction up to the finished end product in the metal forming technology.

From the standard version to the special production, from single workpieces to entire series: Tailor-made precision solutions are the company’s strength.

MASS PRODUCTION

FOR INDUSTRIAL APPLICATIONS

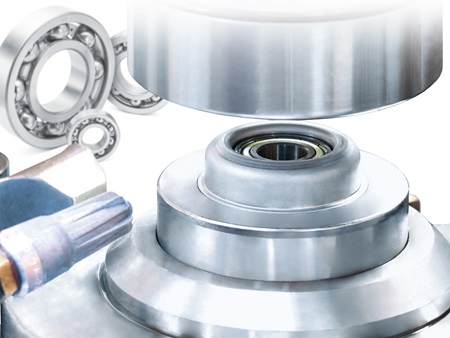

Pressed in LFD deep groove ball bearings

In a separate work process, the matching and sealed LFD deep groove ball bearings are pressed in. For many applications in logistics, the use of high-quality deep groove ball bearings is an economical and reliable solution.

Endurance test benches prove the consistent quality of these important safety-relevant machine parts. Contrary to ordinary bearings, the ball bearings in support roller engineering are installed under tension. With the use of identical materials in all roller components additional loads as a result of thermal expansion are avoided.

In the event of particularly high loads in the bulk goods industry, it should be verified whether spherical roller bearings or self-aligning ball bearings are the better choice as they are able to compensate for each deflection of the rollers with greater success.

Bearings with very good delivery performance

The bearings are distributed worldwide in 20 feet shipping containers to both LFD sales locations as well as directly to the customer. “The factor of time is very important when we want to deliver bearings just-in-time to the assembly lines of our customers”, Veit Loeffler, managing director of the LFD Group, explains. “We have reliable logistics partners for this task. An ever increasing rate our customers work globally and we follow the customers to wherever our products are required.

If necessary, an appropriate sales organisation and a warehouse is constructed onsite”, Veit Loeffler describes the possibilities for customers. “Currently, we deliver our bearings to 68 countries.

It is the objective of our logistics to create short distances for our customers.” The company is now represented on all continents. In addition to the central warehouse in Germany, the LFD Group also has further storage capacity in France, Italy, the USA, Chile and Shanghai.

Additional representative offices and partners facilitate quick response times, ensuring that customers can be offered the fastest possible delivery. During the development and manufacture of all types of bearings, the company from Dortmund focuses precisely on the application of the respective customer.