LFD Product testing

As soon as a new container is delivered from the company’s own plants to the works premises of the LFD Group in Dortmund, this docks at one of the 23 gates of the modern dynamic storage facility and is unloaded.

According to EU law, the LFD Group is responsible for all products that it imports into the EU. In this manner, LFD is interpreted as the “quasi manufacturer”. Here it makes no difference whether the goods origin ate from LFD’s own in-house production or from audited plants. For this reason, the company performs separate product quality testing in accordance with DIN ISO 2859.

The buying department links each container shipment to a LEBE no. in the ERP software. With this, the information from the production or from the supplier is linked to the future sales documentation so complete traceability can be guaranteed. Using the issued LEBE no, a test plan is generated by the quality control software for each article. A specified amount is removed based on the test plan and the specifications of DIN ISO 2859. During sampling, the first visual inspections are performed. Here, the pallet, box and bearing are examined for visual damage or contamination. Then the sample specimens are taken to the testing laboratory.

The following is also tested:

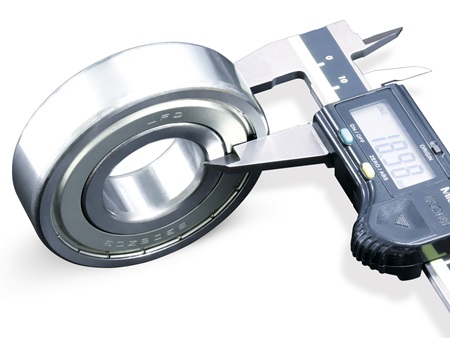

- Outside and inside diameter

- Width of the inner and outer race

- Hardness of the steel of both the inner as well as the outer race (performed according to the Rockwell

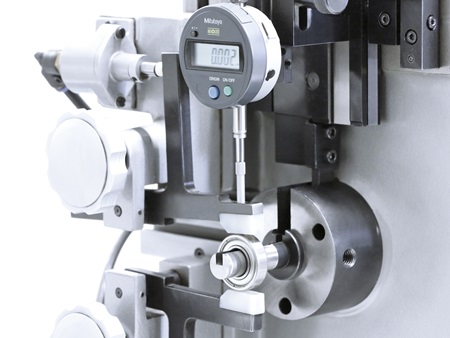

method) - Bearing clearance

- Weight

- Rotation

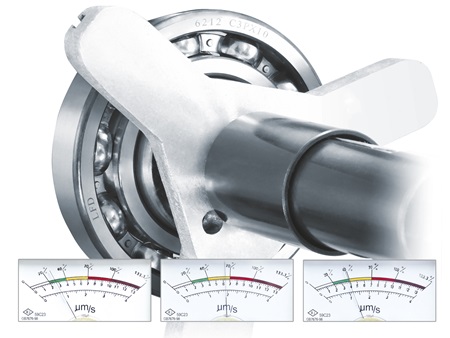

- EMQ bearings (electric motor quality) are additionally subjected to a structure-borne noise measurement (μm/s). There, the respective bearings are tested in the low frequency range for possible out-of-roundness and in the medium and high frequency range for possible damage.

Following the successful test, the goods are stored.

Testplans for each bearing type

At LFD, all orders including the test plans for all bearing types are stored in the quality control software. Additionally, clearly arrange charts are affixed to the walls in the laboratory for all test processes, which also present the corresponding tolerances for each bearing type.

The test plan specifies the tests that are to be performed. Accordingly, tests are carried out for the dimensions, hardness, bearing clearance, noise, drawing dimensions and many more factors.

Each individual bearing is subjected to all tests. The individual results are stored automaticallyin the quality control software and evaluated according to their AQL key.

Additionally, the batch code is stored, which is specified on each single bearing. In this manner, LFD can trace each bearing back to its origin using the batch codes or with the use of the delivery note number. In this manner, information can be queried at any time on the measurement data.

Bearing materials:

Effects on the service life

Material suitability

The suitability of materials for bearings results from the manifold requirements set in regard to performance.

During the selection, criteria such as loading capacity and resistance to corrosion or temperature are a supporting factor. High requirements are generally set in regard to the loading capacity of the individual bearing components such as races, cages and balls.

LFD meets these requirements with the selection of particularly pure steels with an oxygen content that is as low as possible.

Chromium steels that have been hardened through with approx. 1% carbon and 1.5% chromium content have established themselves worldwide, which are well suited for the hardening to 58-65 HRC (Rockwell hardness scale).

Bearing clearance with support rollers

The LFD bearing design is optimized in regard to the bearing track lubrication in combination with the matching bearing play. Because the maximisation of the service life is directly dependent on the bearing clearance.

The aspect of tilting gains in importance with the increasing roller length, as the deflection of the support rollers leads to ever greater tilting in the bearing position. LFD takes these aspects into consideration in its own production.