Roller technology - individual solutions

The requirements in regard to the roller technology are as diverse as the industry sectors, in which they are used.

The transported goods differ in regard to size, weight and surface quality and furthermore in regard to the quantity, which is to be transported.

The engineers of ROS RollenTechnik in Kastl develop the suitable technical solutions for all of these conditions and specific challenges. Expert knowledge of conveyor roller production comes into effect in all areas where interruptionfree, efficient and low-maintenance conveyor technology and a smooth transport of parcel goods and material plays a central role in the internal flow of goods.

In-house planning

Thanks to in-house planning and made-to-measure production, the company delivers a variety of roller systems for transport goods to a multitude of industry sectors. This includes the mining industry, iron and steel industry, mechanical engineering & vehicle industry, chemical industry, consumer goods industry as well as the recycling and waste industry.

Uninterrupted flow of goods

Individual requirements for the roller construction

Here, each field of application is faced with very specific challenges in regard to the conveyor system, which ensures the interruption-free flow of goods:

Strict safety requirements in the chemical industry, highest precision in the pharmaceutical industry, high degree of robustness and stability in the steel industry, maximum range of different goods in the consumer goods industry.

However, common to all is a maximum degree of reliability, durability and perfect functionality of the roller technology.

Complete roller conveyors

Complete roller conveyors from the business segment of ROS FörderTechnik are used on standardized in-house transport requirements in the supply and removal area of machines and systems.

The product range includes non-driven and driven roller conveyors, project-related special solutions as well as accumulation roller conveyors (with accumulation coupler in the roller) and curved roller conveyors. Roller conveyors for light, moderate and heavy loads are offered.

Support rollers

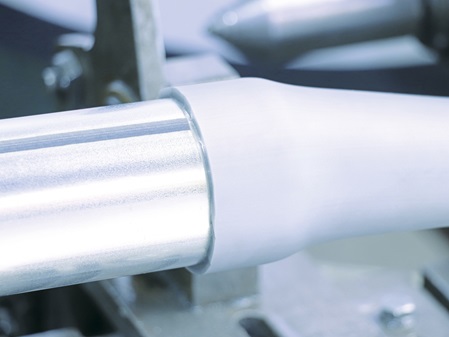

Support rollers for light to moderate loads are in particular used inthe parcel goods sector. A distinction is made between driven and non-driven support rollers. The range includes numerous possibilities for variation.

Selection and combination of different pipe and axle variants are just as possible as the use of different materials during support roller applications or different drive types.

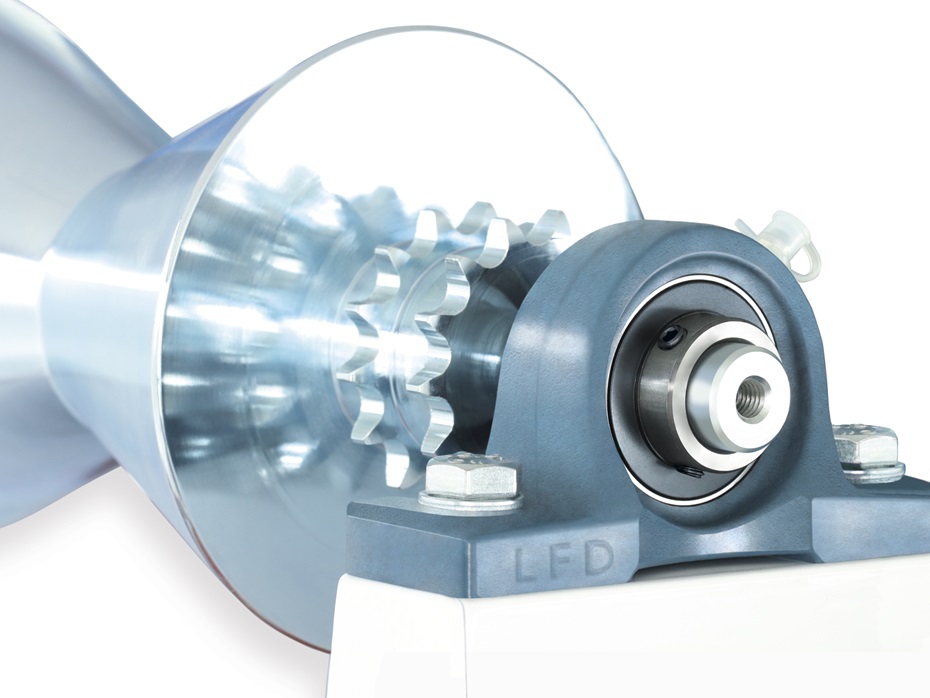

LFD deep groove ball bearings,

spherical roller bearings

and self-aligning ball bearings

On deep groove ball bearings, as the name already suggests, the balls run in a groove. The bearing track is determined to a few thousands of a millimetre, from which the balls cannot deviate. Only slanted positions, out-of-true, bent shafts, etc. lead to the risk of bearing damage.

Support rollers with LFD-Bearings

Because ball bearings are designed for radial loads. Therefore, in the event of particularly heavy loads, it is recommended to use LFD spherical roller bearings or self-aligning ball bearings.

The latest engineering standards must be taken into account during the development and production, furthermore a high degree of reliability and a long service life of the LFD bearings under the most challenging operating and environmental conditions must be ensured. Additionally, the worldwide use of the conveyor systems requires taking a variety of standards into account such as UNI, ISO, Afnor, Cema and BS standards.

Support rollers with LFD bearings enable the implementation of a varied range of conveyor and storage systems. They are matched in regard to dimensioning and material quality (e.g. the type of the surface structure) exactly to the requirements of the conveyer task and the respectively conveyed material. As a result, roller systems made by ROS RollenTechnik can be designed for nearly every intended purpose. In the course of this, various roller types and bearings are used. System failures can lead to high costs and for this reason must be avoided as much as possible. Rollers selected optimally for the application with use-optimised bearings effectively support this objective and can additionally decrease the maintenance effort involved.

Heavy load support rollers

Heavy load support rollers for moderate to high loads are used in both the parcel goods sector as well as with bulk material. The main differentiation is performed here according to inboard and outboard heavy load support rollers.

With inboard heavy load support rollers, in addition to LFD precision deep groove ball bearings, LFD self-aligning ball bearings and LFD spherical roller bearings are used. Again, driven support rollers can be used here. Furthermore, the selection of different pipe and axle variants is possible.

Special support rollers

Special support rollers are matched to the individual needs and requirements of our customers. The intended purpose of the roller among others has an influence on the material selection, coating and hardening process and on specific geometric shapes of the roller body. Special support rollers represent a variation of support rollers and heavy load support rollers.

Sealing systems

protect bearings in support rollers

Special sealing systems with support rollers are well suited for the protection against environmental influences such as dust loads, contamination, water contact and high temperature loads, in particular at locations where high temperature differences occur between day and night.

The chosen lubricating greases are sufficient for operating temperatures ranging from -40 °C to +100 °C. In the event of higher temperatures, special bearings, greases and seals should be used. However, in this case, the grease is less of a topic for the bearing manufacturer.

The manufacturers of conveyer systems will perform the greasing of the open bearings during the installation of the support rollers in a manner that suits the future operating conditions themselves. Conveyor systems, which are intended for the transportation of aggressive substances, are usually fitted with plastic support rollers.

In salt mining, the chemical industry and the fertilizer industry for example require such rollers just as conveyor systems used on sea and in ports. These rollers have a high resistance against humidity or water and also against aggressive environmental conditions and/or materials.

Colourful roller world

Different coatings, glaring colours

The versatility of ROS RollenTechnik is also shown in the various coatings. Even glaring colours, matching the specific corporate design of a company, are conceivable in corresponding quantities.

Possible are support rollers wrapped with PVC cover tubes for the gentle transport, e.g. in the furniture industry. For the reduction of noise and to protect the conveyed material, support rollers can be produced with rounded hot vulcanization (rubber, NBR) in different colours and in individual layer thickness. Furthermore, flocked rollers in various colours and flocking properties are featured in the product portfolio.

LFD bearings:

Energy-efficient, low noise and powerful

The selection of the right bearings provides a contribution to the marked noise reduction just as a – suitable for the specific application – branded lubricant. A significant task of the lubricant lies in reducing or preventing the metallic friction of the bearing components utilising the separating film of lubricant. Not least as a result of this, the implemented bearings are able to run energy-efficiently, with low noise and still powerful.

Quality management according to German standards is a matter of course for all production sectors of the LFD Group. As a result, LFD bearings are extraordinarily loadable even under extremely harsh conditions.

LFD ensures these requirements with its own laboratory equipment and test benches.

Conveyor components

for special applications

Diabolo rollers

The special support rollers also include the diabolo rollers, which have this designation due to their geometric shape. These are primarily used during the transportation of round material. This can for example be a feed for a pipe or bolt saw system, which facilitates the handling of heavy steel pipes or rolled round steel.

The angle of the roller can be produced independently depending on the requirement or according to the size of the round material. Due to the weight that is to be transported by such rollers, these are usually installed with pillow block bearing units.

Bearing unit LFD-ONE

The new range of bearing units LFD-ONE is the result of the greatest possible weight optimization, without neglecting stability and strength. The outer races are spherical, so that the bearing can be adjusted in the concave housing.